+86 13794985240

+86 13794985240

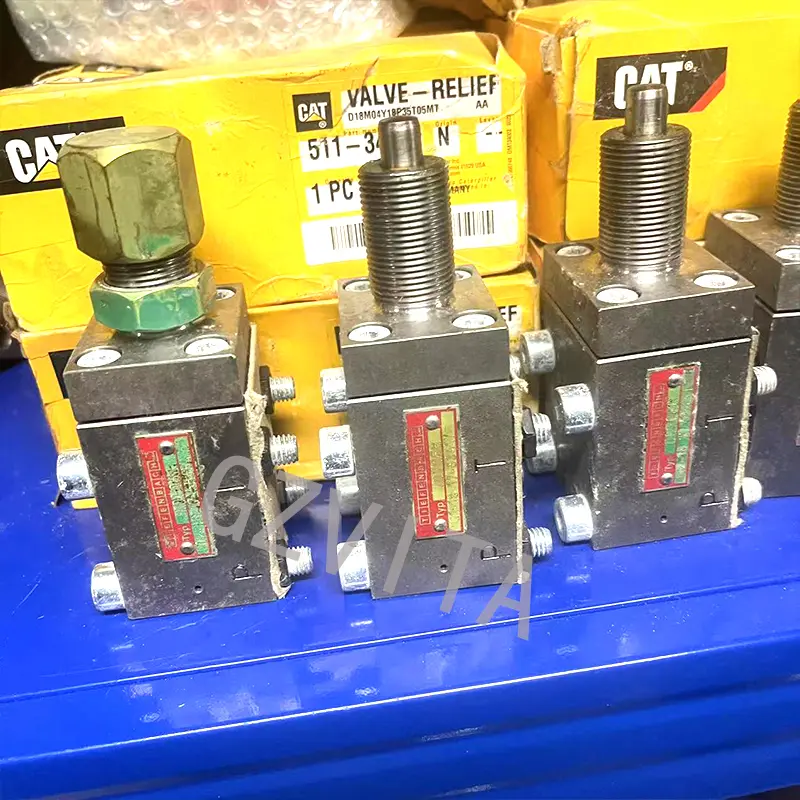

CAT original Relief valve 511-3442 For CAT machinery 5113442

How many relief valves are needed on an excavator?

The number of relief valves used on an excavator can vary depending on the specific model and design of the machine. However, most excavators typically have multiple relief valves to ensure safe and efficient operation. Here are some common types of relief valves found on excavators:

Main Relief Valve

This is usually the primary relief valve that protects the hydraulic system from excessive pressure. It is typically located in the hydraulic pump circuit.

Pilot Relief Valves

These valves are used in the pilot control system to regulate the pressure for the control circuits, ensuring that the operator can control the machine’s functions smoothly.

Auxiliary Relief Valves

If the excavator is equipped with auxiliary hydraulic functions (such as for attachments like grapples or hammers), there may be additional relief valves dedicated to those circuits.

Boom and Arm Relief Valves

Some excavators have specific relief valves for the boom and arm circuits to prevent overloading and ensure safe operation during lifting and digging.

In summary

while the exact number of relief valves can vary, excavators generally have several relief valves to manage different hydraulic circuits and ensure safe operation. For precise information, it is best to refer to the specific excavator’s service manual or technical documentation.