+86 13794985240

+86 13794985240

0102030405

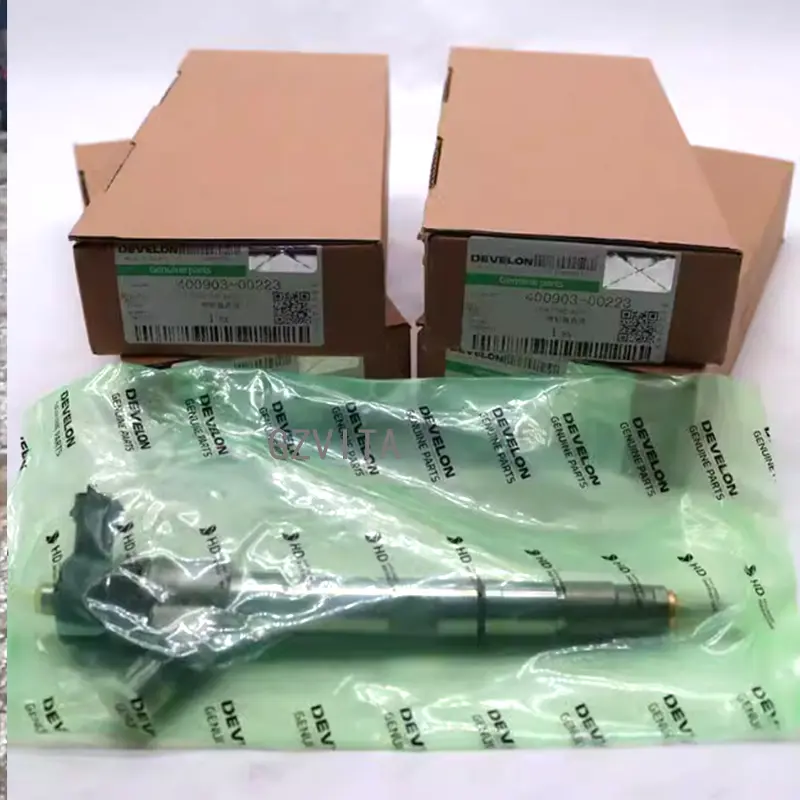

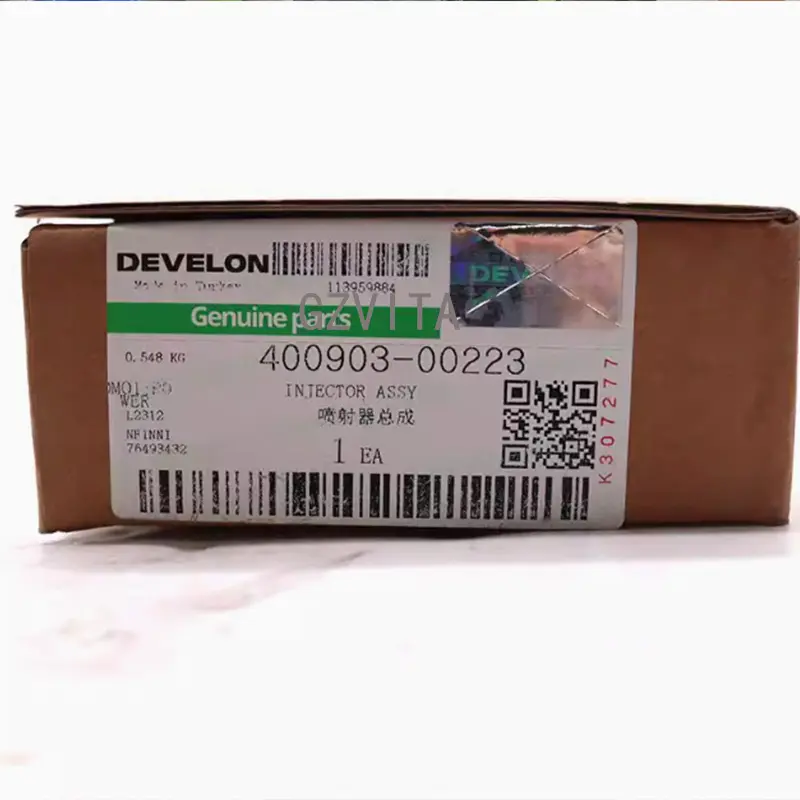

Doosan Fuel Injector Assy 400903-00223 Develon Genuine Parts D18 D24

The notice during the production of the Doosan fuel injector

- Quality Control Standards:Guidelines on maintaining quality throughout the production process, including inspection points and testing procedures.

- Safety Protocols:Instructions to ensure the safety of workers, including the use of personal protective equipment (PPE) and emergency procedures.

- Production Schedules: Timelines for production runs, including deadlines for different stages of manufacturing.

- Material Specifications: Details on the types of materials to be used, including any certifications required for those materials.

- Equipment Maintenance:Notices regarding the maintenance of machinery used in the production process to ensure optimal performance.

- Environmental Compliance: Guidelines to ensure that production processes comply with environmental regulations, including waste management and emissions control.

1. Raw material inspection

- Supplier Audit:Evaluate and audit raw material suppliers to ensure they meet quality standards.

- Material Testing:All incoming raw materials are tested for physical and chemical properties to ensure they meet design requirements.

2. Production process monitoring

- Process Control:Use statistical process control (SPC) tools during production to monitor key parameters (such as temperature, pressure, flow, etc.).

- Real-time data logging:Use automated systems to record production data for easy tracking and analysis.

3. Technology Standards

- Standard Operating Procedure (SOP):Develop detailed SOP to ensure that each operator can operate in accordance with the standard.

- Process Validation: Regularly validate the production process to ensure its effectiveness and consistency.

4. Intermediate product inspection

- Phase inspection:Conduct quality inspections on intermediate products at key stages of production to identify potential problems in a timely manner.

- Functional testing:Perform functional testing on intermediate products to ensure that they meet design requirements.

5. Final product testing

- Full Testing:After the product is completed, it undergoes a full performance test including spray pressure, spray pattern and durability testing.

- Certificate of Conformity:Each qualified fuel injector shall be accompanied by a test report and a certificate of conformity.