+86 13794985240

+86 13794985240

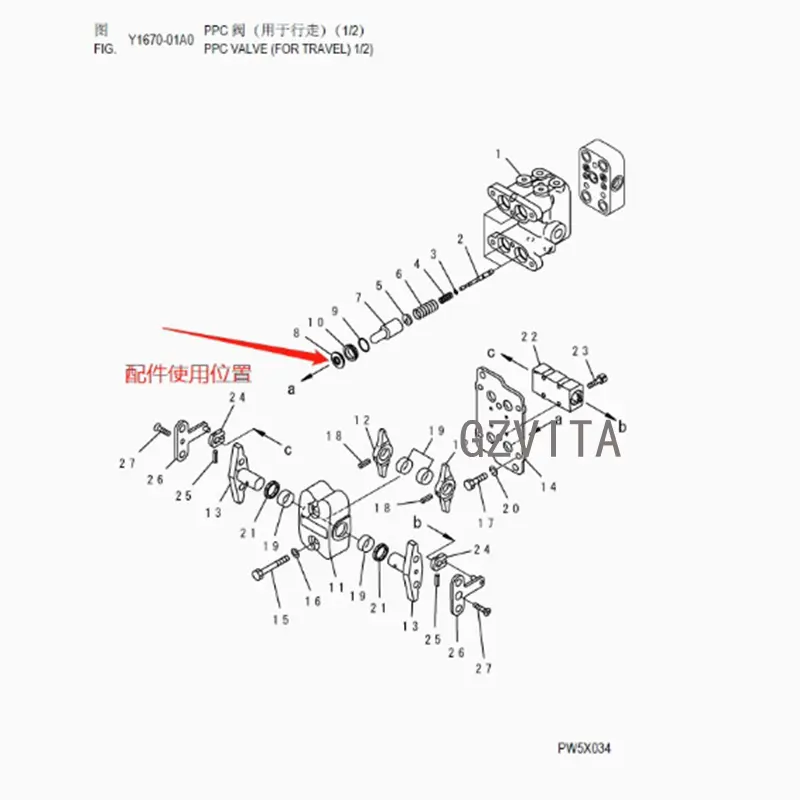

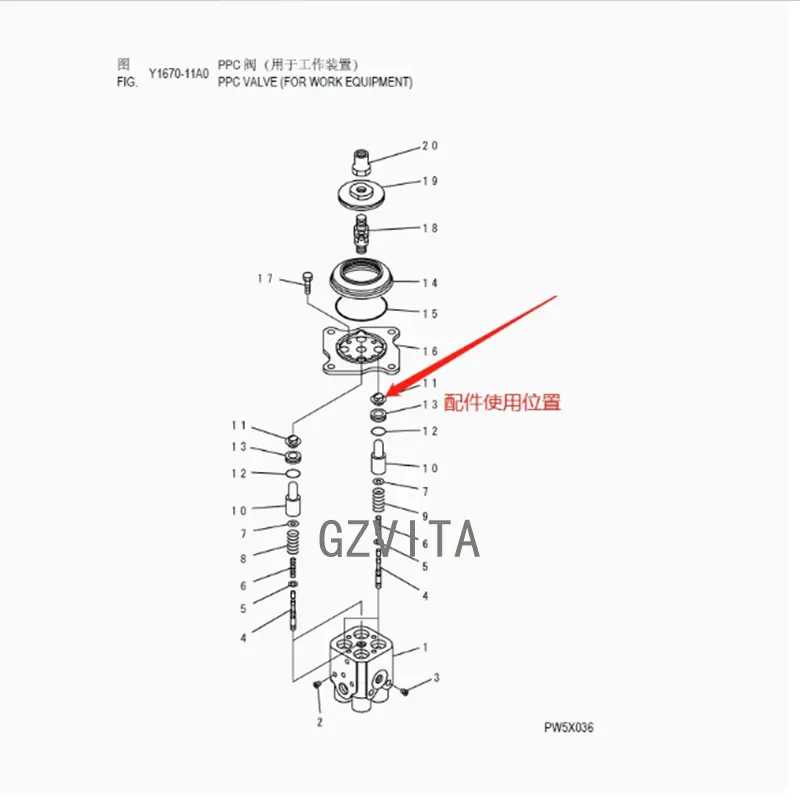

Joystick Pilot Valve Oil seal 8702-16-71210 For PC200 PC220

The Importance of Joystick Pilot Valve Oil Seal for an Excavator

The joystick pilot valve oil seal is a critical component in the hydraulic system of an excavator. It plays a vital role in ensuring the efficient and reliable operation of the joystick control system, which is essential for maneuvering the excavator’s various functions. Here are several key points highlighting the importance of the joystick pilot valve oil seal:

1. Leak Prevention

Hydraulic Fluid Containment: The primary function of the oil seal is to prevent hydraulic fluid from leaking out of the joystick pilot valve assembly. This containment is crucial for maintaining the hydraulic pressure necessary for the excavator’s operation.

System Integrity: By preventing leaks, the oil seal helps maintain the integrity of the hydraulic system, ensuring that all components function as intended without loss of pressure or performance.

2. Operational Efficiency

Smooth Operation: A properly functioning oil seal ensures that the joystick pilot valve operates smoothly. This smooth operation translates to precise control of the excavator’s movements, allowing for better handling and maneuverability.

Reduced Wear and Tear: By preventing hydraulic fluid leaks, the oil seal helps reduce wear and tear on other components of the hydraulic system, leading to longer service life and reduced maintenance costs.

3. Safety Considerations

Preventing Hydraulic Failures: Leaks in the hydraulic system can lead to catastrophic failures, posing safety risks to operators and nearby personnel. A reliable oil seal minimizes this risk by ensuring that the hydraulic fluid remains contained.

Environmental Protection: Preventing hydraulic fluid leaks also helps protect the environment from contamination, which is essential for compliance with environmental regulations and maintaining a safe worksite.

4. Cost-Effectiveness

Maintenance Savings: Regularly inspecting and replacing worn or damaged oil seals can prevent more significant issues down the line, such as complete valve failure or extensive hydraulic system repairs. This proactive maintenance approach can save costs in the long run.

Minimized Downtime: By ensuring that the joystick pilot valve operates correctly, the oil seal contributes to reduced downtime for the excavator, allowing for more efficient project completion and increased productivity.

5. Compatibility and Performance

Material Quality: The quality of the oil seal material is crucial for its performance. High-quality seals can withstand the harsh conditions of an excavator’s operating environment, including exposure to hydraulic fluids, temperature variations, and mechanical stress.

Proper Installation: Ensuring that the oil seal is correctly installed is essential for its effectiveness. Improper installation can lead to premature failure and leaks, negating the benefits of the seal.