+86 13794985240

+86 13794985240

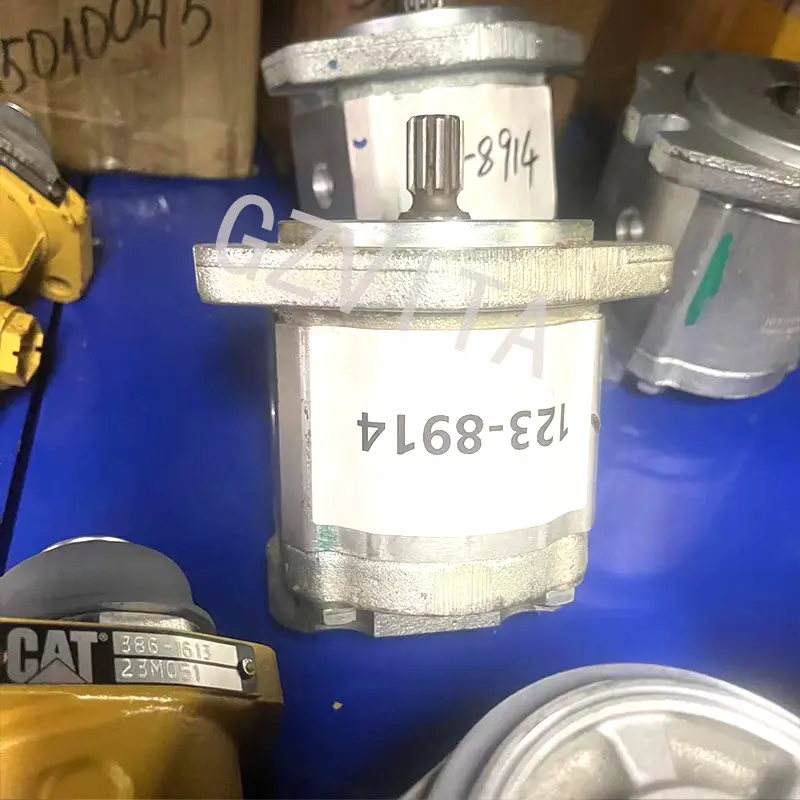

Secondary Steering Pump 123-8914 For Grader 14G 16G 1238914

Introduction to the Secondary Steering Pump for CAT Machinery

The secondary steering pump is an essential component in the hydraulic steering system of CAT (Caterpillar) machinery, particularly in larger equipment such as excavators, bulldozers, and wheel loaders. This pump plays a crucial role in ensuring that operators maintain precise control over their machinery, especially in demanding work environments.

Overview of the Secondary Steering Pump

The secondary steering pump is designed to provide additional hydraulic pressure to the steering system, enhancing the responsiveness and reliability of steering operations. It acts as a backup to the primary steering pump, ensuring that the steering system remains functional even if the primary pump experiences a failure or reduced performance.

Key Functions of the Secondary Steering Pump

Enhanced Steering Control: The secondary steering pump provides additional hydraulic flow, which improves the responsiveness of the steering system. This is particularly important in heavy machinery where precise maneuverability is required.

Redundancy and Safety: In the event of a failure in the primary steering pump, the secondary steering pump ensures that the steering system remains operational. This redundancy is critical for maintaining safety and control, especially in challenging working conditions.

Pressure Maintenance: The secondary steering pump helps maintain consistent hydraulic pressure within the steering system. This consistency is vital for smooth steering operation and helps prevent issues such as steering drift or loss of control.

Support for High-Load Operations: In applications where the machinery is subjected to heavy loads or extreme conditions, the secondary steering pump provides the necessary hydraulic support to ensure that steering remains effective and reliable.

Importance of Maintenance

Regular maintenance of the secondary steering pump is essential to ensure its proper functioning and longevity. Key maintenance practices include:

Routine Inspections: Regularly check the pump for signs of wear, leaks, or damage. Early detection of issues can prevent more significant problems and ensure the reliability of the steering system.

Hydraulic Fluid Checks: Ensure that the hydraulic fluid is at the appropriate level and is free from contamination. Contaminated or low fluid levels can lead to reduced performance and potential pump failure.

System Testing: Periodically test the steering system to ensure that both the primary and secondary pumps are functioning correctly. This testing can help identify any issues before they lead to operational failures.